CDMOs like Particle Sciences contain the gear and personnel set up to each develop and scale-up sterile lyophilization processes.

Manufacturing alternatives and continuous good quality enhancement that established the regular during the pharma industry.

In specific freeze-drying applications, velocity is on the essence. This is where liquid nitrogen arrives into play. It offers a way for swift freezing, making sure that the solution's framework stays intact and reducing the size of ice crystals.

Against this, care needs to be taken to maintain the essential sublimation temperature all over drying, preserve the warmth supply towards the ice-core boundary in equilibrium and avoid overheating the sublimation zone. The first drying stage proceeds right up until the many ice within the solution has become sublimated.

Sublimation heat is not desired on the solution area, but in the boundary with the ice Main that may be withdrawing to the centre with the item as drying proceeds.

Stoppering: This process includes sealing from the vials containing the freeze-dried solution, and it plays a pivotal role in preserving the solution's quality. Correct stoppering makes certain that the product remains uncontaminated and cost-free from exterior dampness, thus preserving its shelf everyday living.

In the course of sublimation, the temperature should generally be kept below the melting temperature from the merchandise. When the temperature rises also quickly or whether it is far too significant, the solution commences to melt which could induce chemical alteration of your merchandise, application of lyophilization in pharmacy foaming up or puffing of your solution cake, loss of risky brokers, lack of particles as They can be boiled, and/or meltback.

Effectiveness cookies are applied to comprehend and evaluate the key effectiveness indexes of the website which assists in providing a better consumer expertise for that readers. Analytics Analytics

Freeze dried materials keep a porous structure. After the freeze drying process is entire, the vacuum is read more usually damaged with an inert fuel before the material is sealed. Most components is usually dried to one-five% residual dampness.

Integration of State-of-the-art refrigeration methods: Exact temperature Regulate is paramount inside the freeze-drying process. The mixing of advanced refrigeration units into fashionable freeze-drying tools gives unparalleled Handle about merchandise temperature.

The end result? A steady, dry powder that could be reconstituted to its first type when wanted, all while maintaining its original potency and efficacy.

This web site will not exist with your picked language. Your desire was saved and you may be notified once a website page is often considered in your language.

In case the vacuum is damaged with untreated sterile air, the products could take in oxygen and drinking water vapor. Just after pre-aeration is entire, the stoppers are sealed into your vials underneath a slight vacuum. Following the stoppers are completely shut, the vacuum is absolutely damaged with sterile air.

Hydrolytically unstable formulation components including PLGA microparticles or fragile APIs could possibly be lyophilized to produce a longer shelf life and accommodate multi-step producing processes. One example is, APIs that go through large Electricity media milling (AKA nanomilling) may be lyophilized previous to incorporation into an oral strong dosage sort.

Dylan and Cole Sprouse Then & Now!

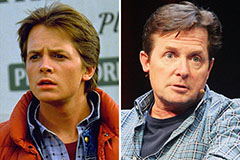

Dylan and Cole Sprouse Then & Now! Michael J. Fox Then & Now!

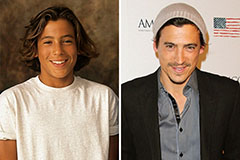

Michael J. Fox Then & Now! Andrew Keegan Then & Now!

Andrew Keegan Then & Now! Macaulay Culkin Then & Now!

Macaulay Culkin Then & Now! Rachael Leigh Cook Then & Now!

Rachael Leigh Cook Then & Now!